3D Modeling Software Upgrades Bring Powerful Analysis Tools to Remote Visual Inspection

Remote visual inspection is a safe, effective nondestructive testing (NDT) method that enables inspection of pipes and other assets without direct inspector access. This approach often uses video borescopes to capture high-resolution footage of pipeline interiors or other hard-to-access areas.

This video borescope footage can be monitored in real time or uploaded for further analysis. And with a few clicks in our 3DAssist™ software, the image data can be turned into 360-degree, 3D models.

3DAssist Software Brings a New Level of Insight into Critical Inspection Areas

Used with our IPLEX™ video borescopes, 3DAssist software turns inspection footage into dynamic 3D models, bringing exceptional details into view. Fully rotatable 3D images of inspection areas—such as rust, thinning, or raised surfaces—let you see details as if you were directly examining the sample. You can closely inspect areas of concern from any location, make definitive assessments, and create and share detailed reports without needing to be in the field.

The software is also easy to use. In the past, generating 3D images with a video borescope required a stereo adapter tip. Today, 3DAssist is the only software capable of creating 3D displays from a video file using a monocular optical adapter. The standard mono tip also captures footage with a wide field of view. This provides a more complete picture as a starting point before the footage is turned into 3D images.

Creating these images requires no special equipment. The process is simple:

- Record your inspection

- Upload the footage from your IPLEX video borescope to your PC

- Select the areas of interest

- Let 3DAssist software process them into easy-to-view 3D images

New Analysis Tools Generate Elevated 3D Images for Stronger Reports

We recently upgraded our 3DAssist software with new features that deliver even more compelling images and valuable inspection data. Designed to enhance remote visual inspection, these powerful analysis tools let you evaluate target areas with greater precision.

Enhancements include reference curved surfaces, color gradient overlays, cross-section profile displays, and advanced image calculations based on the deepest and highest points.

Here’s an overview of these improvements:

1. 3D Scalar Measurement—Now with Point to Curve Mode

3DAssist software features powerful and intuitive 3D scalar measurement modes, including:

- Distance: Measures the distance between two specified points.

- Depth: Measures the distance from a selected point to a reference plane defined by three reference points.

- Point to Curve: A new mode that measures the distance from a selected point to a reference curved surface defined by three reference points.

Designed for precise assessment of bulges and wall thinning, the new Point to Curve mode enables accurate depth and height measurements using a pipe’s surface contour as a reference. This innovative method lets inspectors evaluate defects and target areas with more precision than conventional imaging techniques.

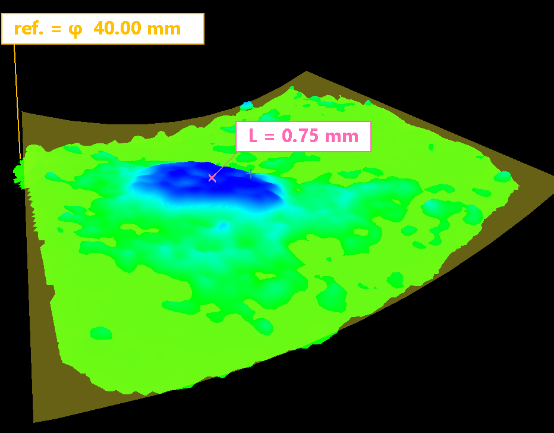

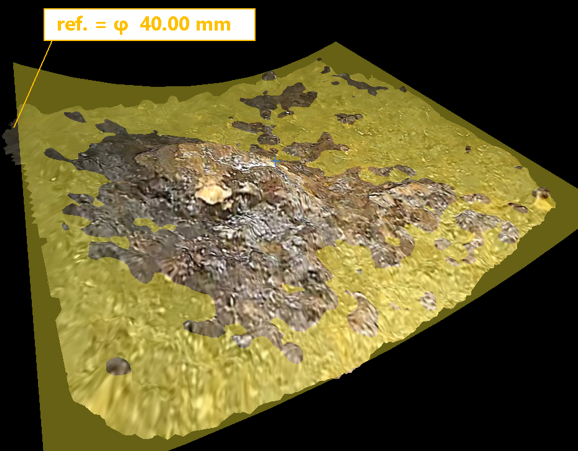

Images from left to right, top to bottom: 1) 3D model of pipe damage. 2) Generation of a reference curved surface using Point to Curve measurement mode. 3) Reference curved surface in a cross-section 3D model.

2. Color Gradient Analysis Based on Height and Depth

3DAssist software’s new Color Gradient analysis function overlays color gradients on object surfaces based on their heights and depths relative to a reference surface. Additionally, this function can adjust color gradient ranges independently based on the direction of surface heights and depths.

Left: 3D model of pipe damage. Right: The same model with Color Gradient analysis.

When used with the Point to Curve measurement mode, Color Gradient analysis helps you identify and interpret higher and deeper areas of the pipe surface at a glance.

Left: 3D model of a raised surface sample. Right: The same model in Point to Curve measurement mode with Color Gradient analysis.

3. Profile Analysis Specified by Chosen Points

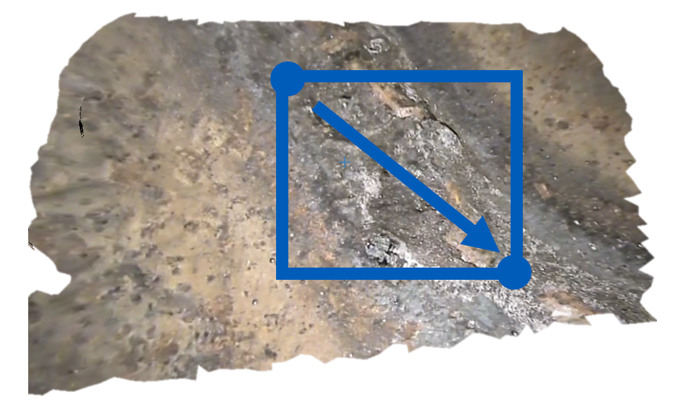

Our new Profile analysis function lets you generate a detailed cross-section of a 3D model based on a user-defined plane, highlighting surface roughness in a specified area. With just two measurement points, you can easily create a cross-section. Once a reference surface is set, the maximum height and depth are calculated and displayed simultaneously. Profile analysis also enables convenient switching between multiple visible surface profiles.

Images from left to right, top to bottom: 1) 3D model of pipe damage. 2) Cross-section profile of a specified area generated using Profile analysis. 3) Alternative view of same profile.

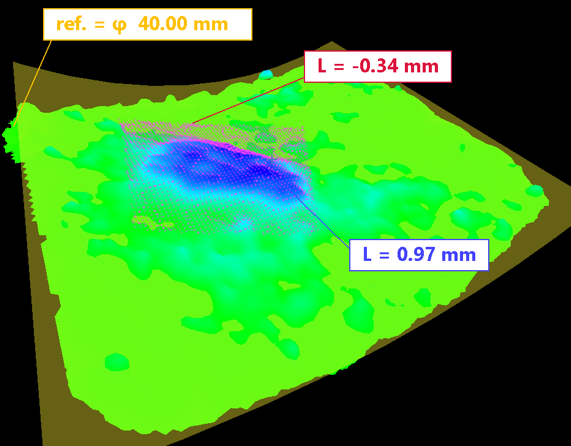

4. Deepest/Highest Point Calculation

Deepest/Highest analysis is a new 3DAssist function that calculates and displays the deepest and highest points in a specified area using two surface reference points. This insight adds clarity and depth to inspection reports by providing precise data on surface irregularities, such as bumps or thinning areas.

Left: 3D model of pipe damage with two selected reference points. Right: Dimensional overlay created using Deepest/Highest analysis, showing the percentage range between the deepest and highest points.

When combined with Point to Curve analysis and Color Gradient analysis, Deepest/Highest analysis enhances inspection reports with exceptional detail, adding a new level of confidence to image interpretations.

Left: 3D model of a raised surface sample. Right: The same model with Deepest/Highest analysis, Point to Curve analysis, and Color Gradient analysis applied.

Easier Ways to Share and Collaborate During Inspections

3DAssist software simplifies inspection of pipes and other assets by enabling more informed decision-making—regardless of physical location. It transforms standard inspection reports into dynamic, in-depth analyses with a range of 3D comparative measurement functions.

3D images can be easily saved to a clipboard and pasted into reports, while models and measurements can be stored and retrieved at any time. In addition, models can be positioned alongside images to provide context. 3DAssist software also streamlines collaboration, enabling you to share images and reports through PC-based tools such as Microsoft Teams.

Designed to help all stakeholders quickly assess defect severity and decide next steps with confidence, 3DAssist software enables the creation of fully rotatable 3D images in a few clicks. These images can then be analyzed and shared directly from the office, reducing the need for field visits. With a suite of powerful analysis functions, your 3D models now provide more insights than ever before.

3DAssist software is compatible with new and existing IPLEX NX, IPLEX GX/GT, IPLEX G Lite, and IPLEX GAir video borescopes. To learn more about how 3DAssist software enhances inspection reports with in-depth analysis, reach out to us today to schedule a demo.